- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- PH Meter HANNA

- INFRARED THERMOMETER MT10

- Lux Meter (Light Meter) LX101A LUTRON

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- Hegman Gauge

- Digital Coating Thickness Gauge DFT-111

- Digital Coating Thickness Gauge Accu-456B

- Digital Coating Thickness Gauge ACCU-356B

- DFT-222 Coating Thickness Gauge

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Rubber Hardness Tester Shore A

- Digital Shore Hardness Tester

- Digital Shore A Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

Press O Film 20 to 64um HT Coarse - Testex

2950.00 INR/Piece

Product Details:

- Weight 50-250 Grams (g)

- Mounting Type Manual application onto surface

- Display Type Analog (with separate gauge)

- Usage For Industrial And Laboratory Use

- Resolution 1 m (with proper gauge)

- Application Surface Profile Measurement

- Max Height 64 m

- Click to View more

X

Press O Film 20 to 64um HT Coarse - Testex Price And Quantity

- 2950.00 INR/Piece

- 100 Number, Number, Number

Press O Film 20 to 64um HT Coarse - Testex Product Specifications

- 50-250 Grams (g)

- Manual application

- Manual application onto surface

- Surface Profile Measurement

- 1 m (with proper gauge)

- 64 m

- For Industrial And Laboratory Use

- Analog (with separate gauge)

- Manual, as needed

- White

- Each pack contains 50 test strips

- 2 (50 mm)

- Testex Press-O-Film Tape

- 44 mm 150 mm

- Single strip per test

- Physical (tape and comparator gauge)

- Not Applicable (Tape Based)

- 20 to 64 m (HT Coarse)

- 5C to 50C (Ambient)

- Instantaneous (manual reading)

- 0-100% RH (Ambient)

- 5%

- Manual

- Provides a permanent mold of surface profile, easy to use, no calibration required, single-use strips

- 20-64 m

- 50-250 g

- Stainless Steel

- Manual

- Sample Strip: 44 mm 150 mm

Press O Film 20 to 64um HT Coarse - Testex Trade Information

- 100 Number, Number, Number Per Day

- 1 Days

- All India

Product Description

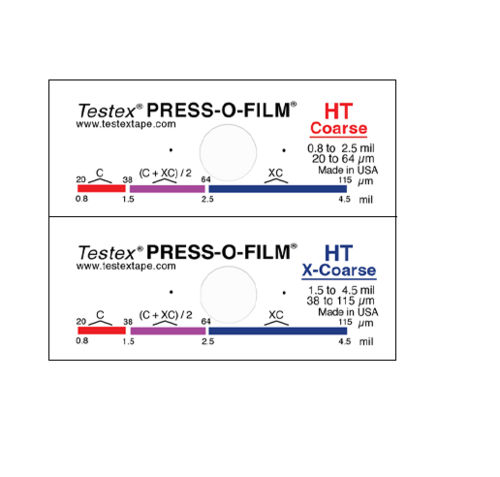

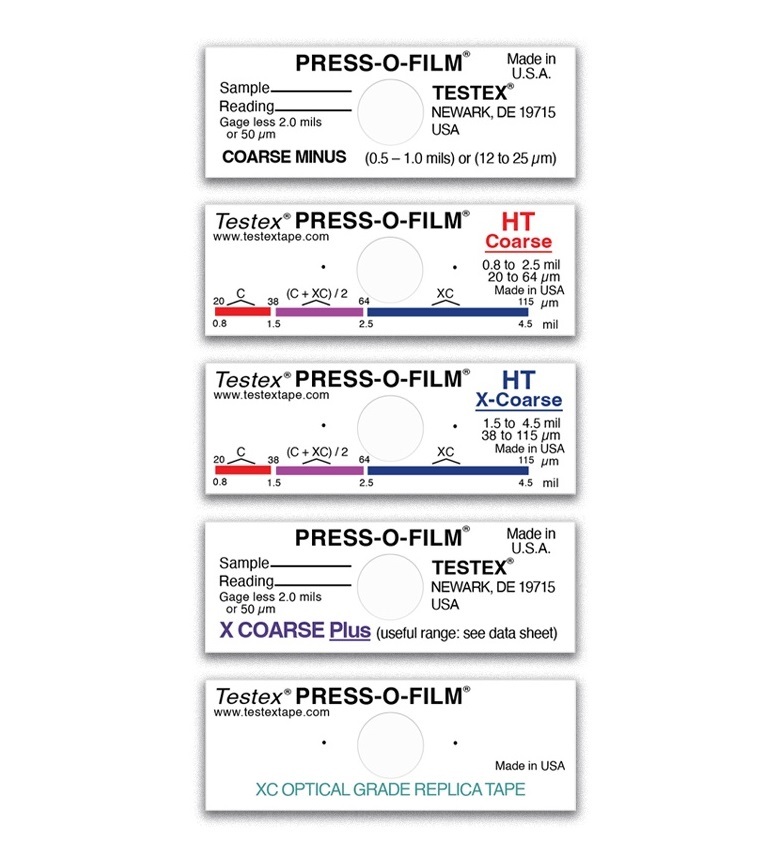

Conventional Testex Press-O-Film Tape Grades

Testex Press-O-Film replica tape is available in a variety of thickness ranges for measuring substrate roughness. The primary range for measurement with replica tape is 20 to 115 m (0.8 to 4.5 mils). Use of Coarse Minus grade (<20 m or <0.8 mil) or X-Coarse Plus grade tape (>115 m or >4.5 mils) should primarily be restricted to checking measurements at the lower and upper ends of the primary range.

Order Code

Grade

Range

Measurement Tool

RTCMIN

Coarse Minus

0.5 to 1.0 mils12 to 25 m

Testex Micrometer

or

PosiTector RTRH

RTC

Coarse

0.8 to 2.5 mils20 to 64 m

RTXC

X-Coarse

1.5 to 4.5 mils38 to 115 m

RTXCPLUS

X-Coarse Plus

4.6 to 5.0 mils116 to 127 m

Reliable Surface Profiling for Industrial Needs

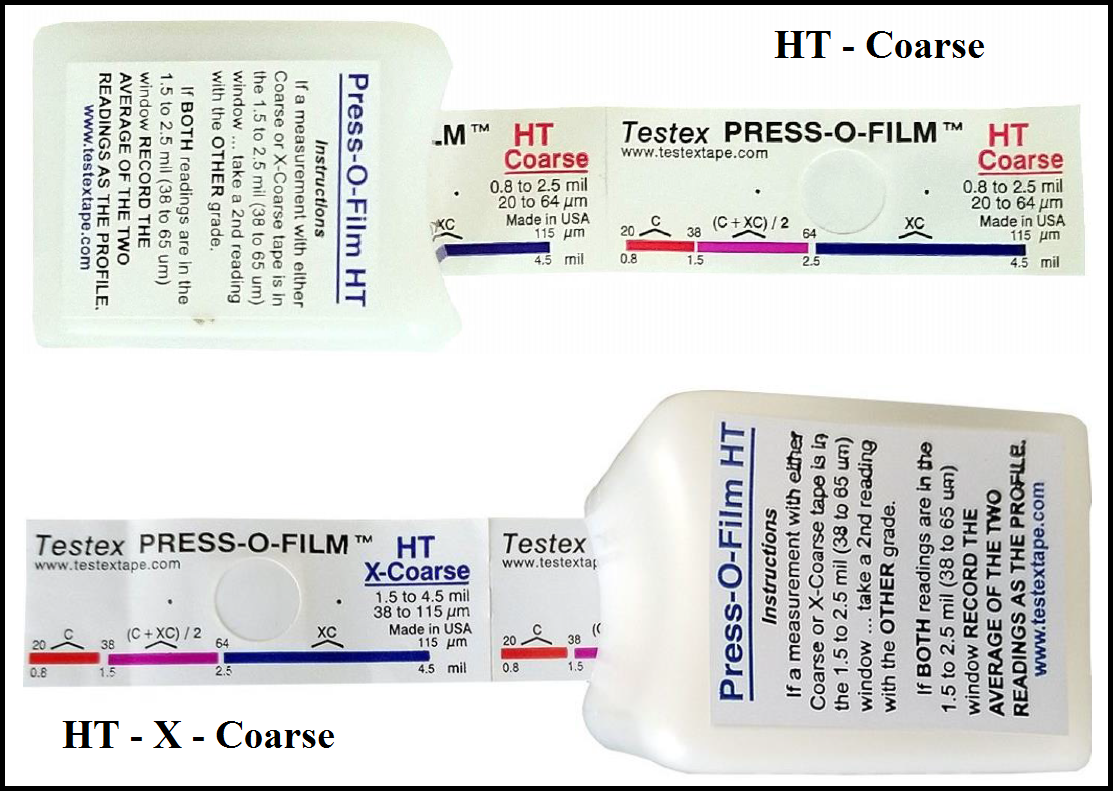

Press O Film 20 to 64um HT Coarse replica tape delivers dependable results in measuring and recording the surface profile of blast cleaned steel. Each single-use strip provides an instant, permanent mold of the measured area, ensuring accurate readings for quality control or compliance tracking across a range of industrial applications.

Effortless Application and Storage

This product is designed for manual use, removing the need for specialized equipment or calibration. Simply mount the strip onto the surface and employ the accompanying analog comparator gauge for reading. Store the strips in their original packaging, dry and away from sunlight, to maintain their usability for up to five years.

FAQs of Press O Film 20 to 64um HT Coarse - Testex:

Q: How do I use Press O Film 20 to 64um HT Coarse to measure surface roughness?

A: To measure surface roughness, manually apply a strip onto the blast cleaned steel surface, press firmly, and remove. Then, use an analog gauge to read the molded profile. Each strip measures the area instantly and provides a permanent record.Q: What surfaces can I test with Press O Film 20 to 64um HT Coarse?

A: These replica tapes are intended for measuring and recording the profile of blast cleaned steel, commonly used in industrial and laboratory environments for quality assessment and surface analysis.Q: When should I replace my test strips during a project?

A: Each strip is designed for single use. For every profile measurement, use a new strip to ensure accuracy and maintain reliable records of the surface condition.Q: Where should I store Press O Film strips to maximize shelf life?

A: Keep the strips dry, in their original packaging, and away from direct sunlight. By following these guidelines, you will preserve the strips and ensure a shelf life of at least five years.Q: What is the benefit of using Press O Film replica tape for surface profiling?

A: The tape offers quick, easy, and precise measurement of surface profiles. It creates a permanent mold of the surface, doesnt require calibration, and is highly effective for manual, on-site assessments.Q: Is any calibration required before using these strips?

A: No calibration is necessary. Simply use the tape with a compatible analog gauge for accurate readings within the measuring range.Q: What is the accuracy and resolution offered by Press O Film 20 to 64um HT Coarse?

A: When used with a proper gauge, the accuracy is 5% and the resolution is 1 m, ensuring reliable results for surface profile measurements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Press-o-film' category

We mainly deal in Gujarat

Back to top