- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- PH Meter HANNA

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge ACCU-356B

- Digital Coating Thickness Gauge Accu-456B

- DFT-222 Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- Digital Coating Thickness Gauge DFT-111

- Hegman Gauge

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Digital Shore Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

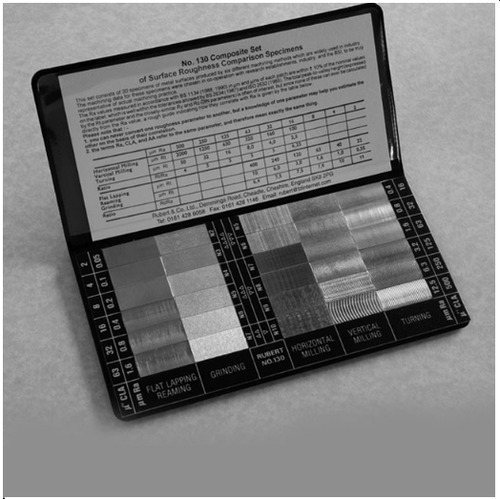

130 Roughness Comparison Specimens

3950 INR/Piece

Product Details:

- Usage For Industrial And Laboratory Use

- Material Stainless Steel

- Grade Industrial Grade

- Color Black And Grey

- Width 10-50 Millimeter (mm)

- Click to View more

X

130 Roughness Comparison Specimens Price And Quantity

- 1 , , Piece

- 3950 INR/Piece

130 Roughness Comparison Specimens Product Specifications

- For Industrial And Laboratory Use

- 10-50 Millimeter (mm)

- Industrial Grade

- Stainless Steel

- Black And Grey

130 Roughness Comparison Specimens Trade Information

- 100 , , Piece Per Day

- 1 Days

- All India

Product Description

We are offering high quality 130 Roughness Comparison Specimens that are used for industrial and commercial applications. The offered specimens are suitable for research purposes and comparison ofroughness of a surface. They are suitable for laboratory work and are highly accurate. They are very efficient and have high end accuracy. The specimens are stored in a safe environment and are very highly used in industrial works. The 130 Roughness Comparison Specimens are very useful and made available in gray and black color.Exceptional Material Quality

Manufactured using industrial grade stainless steel, these roughness comparison specimens exhibit superior durability and resistance to corrosion. Their high level of structural integrity ensures reliable performance through extensive usage in demanding industrial and laboratory settings, reducing maintenance costs and ensuring longevity.

Versatile Industrial Applications

With a width range from 10 to 50 millimeters, these specimens accommodate a variety of surface measurement needs. They are ideal for use during quality control inspections, calibration of measurement equipment, and training sessions for personnel, making them a crucial resource for manufacturing and laboratory operations.

FAQs of 130 Roughness Comparison Specimens:

Q: How are the 130 Roughness Comparison Specimens used in industrial and laboratory settings?

A: These specimens are placed alongside materials or surfaces to visually and tactilely compare and evaluate surface roughness. They facilitate quality control inspections, calibrate measurement devices, and offer hands-on training for personnel.Q: What is the benefit of using industrial grade stainless steel for these specimens?

A: Industrial grade stainless steel provides excellent durability, resistance to corrosion, and consistent surface quality, ensuring that the specimens maintain reliability and precision throughout prolonged industrial and laboratory use.Q: When should these specimens be used during the inspection process?

A: They are typically used during quality assessment procedures, calibration of surface measurement tools, and equipment validation steps in both manufacturing and laboratory environments.Q: Where are these roughness comparison specimens sourced and supplied within India?

A: The specimens are distributed nationwide through established importers, manufacturers, and suppliers specializing in industrial measurement equipment.Q: What is the process for selecting the appropriate specimen width for measurement tasks?

A: The width, ranging from 10 to 50 millimeters, is selected based on the size and geometry of the surface being evaluated, ensuring accurate comparison and suitability for various measurement protocols.Q: How does the usage of these specimens benefit quality control in manufacturing?

A: Using these specimens contributes to greater consistency and reliability in surface roughness assessment, supporting improved product quality, streamlined calibration routines, and enhanced training efficiency for technical staff.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Surface Roughness Gauge' category

We mainly deal in Gujarat

Back to top