- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- PH Meter HANNA

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- DFT-222 Coating Thickness Gauge

- Hegman Gauge

- Digital Coating Thickness Gauge Accu-456B

- Digital Coating Thickness Gauge ACCU-356B

- Digital Coating Thickness Gauge DFT-111

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

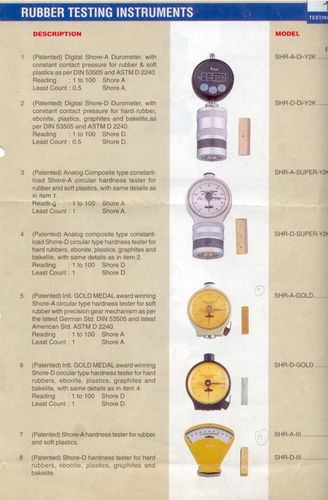

- Rubber Hardness Tester

- Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

shore A Gold

Price 11500 INR/ Piece

MOQ : 1 Piece

shore A Gold Specification

- Specimen Size

- Diameter 35mm, thickness 6mm

- Measuring Range

- 0~100HA

- Operating Voltage

- AC220V 50Hz

- Number of Specimens

- 2

- Frequency

- 50Hz

- Hardness

- Shore A

- Automation Grade

- Manual

- Mounting Type

- Bench-top

- Accuracy

- 1HA

- Response Time

- 1s

- Equipment Type

- Shore A Hardness Tester

- Gas Pressure

- 0.5~0.7MPa

- Display Type

- Digital

- Application

- Rubber, elastomer, plastic hardness test

- Port Size

- Standard

- Features

- Portable, user-friendly, high precision

- Power Supply

- AC220V 50Hz

- Max Height

- ~200mm

- Resolution

- 0.1HA

- Humidity

- 85% RH

- Test Range

- 0~100 Shore A

- Temperature

- Room Temperature

- Usage

- Shore hardness measurement

- Capacity

- Up to 50 samples/hour

- Machine Weight

- About 10kg

- Test Speed

- 10mm/min

- Test Width

- 10mm

- Test Stroke

- 25mm

- Control Mode

- Manual

- Pressure Foot Size

- Diameter 18mm

- Compliance Standards

- ASTM D2240, ISO 868

- Calibration

- Available on request

- Indenter Type

- Hemispherical, radius 0.79mm

- Operation Environment

- Indoor

- Storage Conditions

- Dry, clean environment

- Display

- LCD digital

shore A Gold Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID)

About shore A Gold

Soft vulcanized rubber and all elastometrics, such as: natural

rubber, SBR, neoprene, nitrile rubbers, flexible polyester, cast

resins etc. Also used for wax, felt, leather & other materials such as

cheese cones in textile industry.

Indentor : Truncated cone

Graduation : 1 Shore-A no. (Least Count)

Check Gauge : 25, 50 & 75 Shore-A nos.

Packing : Deluxe wooden box

Dimensions : 150 x 150 x 50 mm

Weight : 600 g

Precision Hardness Measurement for Rubber and Plastics

Engineered for accuracy, the Shore A Gold Hardness Tester provides digital results for materials such as rubber and elastomers. Its advanced hemispherical indenter and LCD display ensure consistent and reliable data collection within the internationally recognized 0-100 Shore A range, making it indispensable for quality control.

Ease of Operation and Robust Build

With its intuitive manual controls, bench-top mounting, and user-friendly interface, this tester facilitates straightforward operation in various laboratory settings. Its durable construction and manageable 10kg weight combine portability with stability, perfect for regular daily use in demanding environments.

Compliance and Versatility

Fully compliant with ASTM D2240 and ISO 868 standards, this hardness tester meets rigorous industry requirements. Compatible with multiple sample types, it processes up to 50 specimens per hour, enhancing efficiency and allowing for comprehensive quality assurance protocols in industrial and research settings.

FAQ's of shore A Gold:

Q: How does the Shore A Gold Hardness Tester measure hardness?

A: The tester utilizes a hemispherical indenter with a 0.79mm radius to press against the material specimen. The resistance is measured and displayed digitally in the Shore A hardness scale, providing accurate assessment of rubber, elastomer, or plastic samples.Q: What types of materials are compatible with this Shore A Hardness Tester?

A: It is specifically designed for measuring the hardness of rubber, elastomers, and various plastics, making it suitable for quality testing, manufacturing, and research applications in these fields.Q: When should calibration be performed on this hardness tester?

A: Calibration is recommended according to your laboratory's quality protocol or whenever consistent accuracy is critical. Calibration services are available on request to ensure precise measurement results.Q: Where is the optimal environment to operate and store this tester?

A: The Shore A Gold Hardness Tester should be operated indoors, maintained at room temperature, and stored in a dry, clean environment to ensure long-lasting performance and accuracy.Q: What is the process for testing a sample with this instrument?

A: Prepare two specimens of size 35mm diameter and 6mm thickness. Place the sample on the test platform, manually control the indenter to apply a 10mm/min speed, and observe the hardness value on the LCD digital display. The standard testing width is 10mm, and the allowable test stroke is 25mm.Q: How can users benefit from employing this instrument in their facility?

A: Users benefit from its high measurement precision (accuracy 1HA), fast response time (1s), and the ability to process up to 50 samples per hour, supporting efficient, consistent, and standards-compliant hardness evaluation in industrial and laboratory settings.Q: What are the key features that enhance the usability of the Shore A Gold Hardness Tester?

A: Key features include its easy-to-read LCD digital display, manual control for user flexibility, robust yet portable 10kg build, compliance with ASTM D2240 and ISO 868, and its suitability for a wide range of hardness measurements up to 100 Shore A.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rubber Hardness Tester Category

SHORE A DIGITAL

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial, Laboratory

Humidity : <80% RH

Resolution : 0.1 Shore A

Test Range : 0100 Shore A

Shore D basic

Price 3200 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial Testing

Humidity : 80% RH

Resolution : 0.5 HD

Test Range : 0~100 HD

Shore A Export

Price 3800 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory testing, field inspection

Humidity : 10% 85% RH

Resolution : 0.5 Shore A

Test Range : 0 100 Shore A

Shore A Basic

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : For rubber, elastomer, plastic, soft materials

Humidity : 10% 90% RH

Resolution : 1 Shore A

Test Range : 0 100 HA

We mainly deal in Gujarat

Back to top

Send Inquiry

Send Inquiry