- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- PH Meter HANNA

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

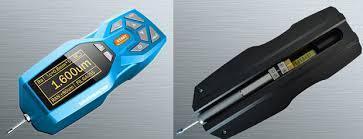

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

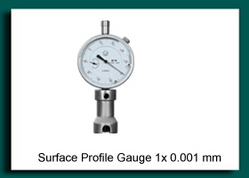

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge ACCU-356B

- Digital Coating Thickness Gauge FM2

- Digital Coating Thickness Gauge DFT-111

- DFT-222 Coating Thickness Gauge

- Hegman Gauge

- Digital Coating Thickness Gauge Accu-456B

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore Hardness Tester

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

SURFACE ROUGHNESS CHART C9 GAR

Price 12000 INR/ Piece

MOQ : 1 Piece

SURFACE ROUGHNESS CHART C9 GAR Specification

- Measuring Range

- 2 to 115 microinch (0.05 to 2.92 micron)

- Display

- Visual comparison, no electronic display

- Case

- Metal, with protective sleeve

- Outer Size

- Size: 7 x 2-3/8 (178 mm x 60 mm)

- Material

- Polished Stainless Steel reference plates, anodized aluminum body

- Grade

- C9

- Application

- Comparison of surface finish roughness for machinists, inspectors, and engineers

- Accuracy

- Certified within 10% of nominal value

- Number of Specimens

- 30 precision marked specimen areas

- Finish Type Coverage

- Ra (Arithmetic Average Roughness), RMS (Root Mean Square), Micron, Microinch values

- Standard Finishes Included

- Grinding, Lapping, Milling, Turning, Shaping, Reaming, Drilling, and Other Common Machining Processes

- Identification

- Each specimen area etched with roughness value and type of machining process

- Product Code

- C9-GAR

- Packaging

- Supplied in padded case with transparent cover

- Usage

- For checking, measuring, and comparing surface roughness; instruction panel included

- Weight

- Approx. 180 grams

- Operating Environment

- Ambient, not suitable for liquids, oils, or excessive dust

SURFACE ROUGHNESS CHART C9 GAR Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash on Delivery (COD)

About SURFACE ROUGHNESS CHART C9 GAR

The SURFACE ROUGHNESS CHART C9 GAR commands a remarkable Spotlight among industry professionals, earning Favorable Reviews for its Top-notch precision and resplendent design. Accommodating 30 meticulously-marked specimen zones, this indispensable tool covers standard finishes-including Grinding, Lapping, Milling, Turning, and more. Crafted from polished stainless steel and anodized aluminum, it delivers inestimable value through accurate, certified performance (10%). Suitable for machinists, inspectors, or engineers, it visually compares Ra, RMS, micron, and microinch values. Each purchase is a Hot deal, complete with a protective case, making it a reliable addition to any workspace.

Versatile Applications & Precision Usage

The SURFACE ROUGHNESS CHART C9 GAR is designed for both general and specific uses in machine shops, calibration facilities, and engineering environments. It enables users to check, measure, and compare fine surface roughness across various standard machining processes, with each reference area visually etched for quick identification. Ideal for machinists, inspectors, and engineers, its application media is strictly ambient-unaffected by liquids, oils, or excess dust-ensuring surefire comparisons and consistent accuracy for everyday or specialized use.

Flexible Payment Terms & Seamless Handover

For the SURFACE ROUGHNESS CHART C9 GAR, payment is customizable with competitive asking prices based on order volume and client requirements. Handover of the chart occurs at the specified drop-off or pick-up point, typically at our FOB port in India, ensuring timely and secure delivery. Sample policy is customer-focused-samples are provided upon request to help you confidently assess quality before any large-scale investment, streamlining the acquisition process and facilitating trust in every transaction.

Versatile Applications & Precision Usage

The SURFACE ROUGHNESS CHART C9 GAR is designed for both general and specific uses in machine shops, calibration facilities, and engineering environments. It enables users to check, measure, and compare fine surface roughness across various standard machining processes, with each reference area visually etched for quick identification. Ideal for machinists, inspectors, and engineers, its application media is strictly ambient-unaffected by liquids, oils, or excess dust-ensuring surefire comparisons and consistent accuracy for everyday or specialized use.

Flexible Payment Terms & Seamless Handover

For the SURFACE ROUGHNESS CHART C9 GAR, payment is customizable with competitive asking prices based on order volume and client requirements. Handover of the chart occurs at the specified drop-off or pick-up point, typically at our FOB port in India, ensuring timely and secure delivery. Sample policy is customer-focused-samples are provided upon request to help you confidently assess quality before any large-scale investment, streamlining the acquisition process and facilitating trust in every transaction.

FAQ's of SURFACE ROUGHNESS CHART C9 GAR:

Q: How is the SURFACE ROUGHNESS CHART C9 GAR used in practical settings?

A: It is used for checking, measuring, and visually comparing surface roughness by matching machined parts to marked specimen areas, which represent a wide range of common machining finishes.Q: What processes and finishes are included in this chart?

A: The chart covers Grinding, Lapping, Milling, Turning, Shaping, Reaming, Drilling, and other prevalent machining processes, with 30 precision-marked specimen areas showing Ra, RMS, micron, and microinch values.Q: Where should I use the SURFACE ROUGHNESS CHART C9 GAR?

A: It is intended for use in ambient environments such as machine shops or laboratories. Avoid application in the presence of liquids, oils, or excessive dust to preserve its accuracy and integrity.Q: What are the main benefits of using this roughness chart?

A: This chart offers top-notch accuracy (within 10% of nominal value), quick visual comparison for multiple machining processes, and high durability due to its polished stainless steel and anodized aluminum construction.Q: What is the process for purchasing and receiving the chart?

A: You can inquire about the asking price and payment options, arrange for sample delivery, and coordinate chart drop-off at the designated FOB port in India for seamless handover.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Surface Roughness Gauge Category

Roughness Tester

Price 52500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Width : 1050 Millimeter (mm)

Usage : For Industrial And Laboratory Use

Grade : Industrial Grade

surface roughness tester accu 120

Price 48000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Width : 1050 Millimeter (mm)

Usage : For Industrial And Laboratory Use

Grade : Industrial Grade

Surface Roughness Tester Accuplus

Price 85000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Width : 1050 Millimeter (mm)

Usage : For Industrial And Laboratory Use

Grade : Industrial Grade

Surface Profile Gauge

Price 6500.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Width : 1050 Millimeter (mm)

Usage : For Industrial And Laboratory Use

Grade : Industrial Grade

We mainly deal in Gujarat

Back to top

Send Inquiry

Send Inquiry