- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- PH Meter HANNA

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- DFT-222 Coating Thickness Gauge

- Hegman Gauge

- Digital Coating Thickness Gauge Accu-456B

- Digital Coating Thickness Gauge ACCU-356B

- Digital Coating Thickness Gauge DFT-111

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

200 X 200MM MASTER LEVEL

Price 18000 INR/ Piece

MOQ : 1 Piece

200 X 200MM MASTER LEVEL Specification

- Sensor Type

- Bubble Vial

- Resolution

- High Precision (0.02 mm/m)

- Measurement Range

- 200 x 200 mm

- Humidity %

- 0-80% (non-condensing)

- Equipment Type

- Master Level

- Temperature Range

- -10C to 50C (operating)

- Material

- Hardened Steel

- Power Supply

- No power required (manual operation)

- Accuracy

- 0.02 mm/m

- Display Type

- Bubble/Spirit Vial

- Range

- 200 x 200 mm

- Finish

- Precision ground and lapped

- Dimensions

- 200 mm x 200 mm x 40 mm

- Edges

- Beveled edges for easy aligning

- Finish Type

- Corrosion resistant coating

- Vials

- 2 (Horizontal and Vertical)

- Weight

- Approx. 2 kg

- Color

- Metallic silver with black details

- Application

- Precision leveling and calibration

200 X 200MM MASTER LEVEL Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID)

About 200 X 200MM MASTER LEVEL

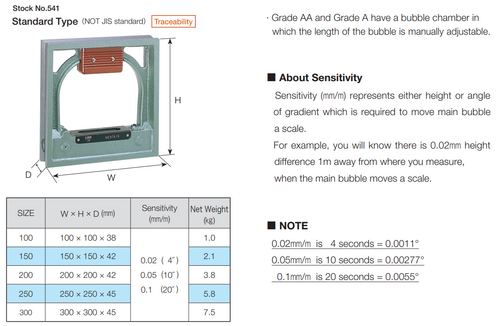

Grade AA A and B are manufactured and inspected

under the JIS B 7510 standard

See P5 for further information on each grade

Grade AA has 02 scale all range accuracy in the

main bubble

These three types have less than 3m accuracy in

flatness between base and side 002mmm type

Squareness between base and both side is 0015mmm

002mmm for Grade A

Grade AA and Grade A have a bubble chamber in

which the length of the bubble is manually adjustable

Exceptional Precision and Durability

Manufactured from high-grade hardened steel, the MASTER LEVEL ensures longevity and maintains its precise calibration over years of use. The finish is both corrosion-resistant and meticulously ground and lapped, guaranteeing stable, repeatable measurements in every environment. Its rugged design makes it suitable for workshops, laboratories, and onsite calibration tasks.

Advanced Features for Professional Applications

This master level incorporates two precise spirit vials for horizontal and vertical measurement, allowing comprehensive leveling in multiple orientations. The beveled edges promote easy alignment, and the display uses traditional bubble vial technology, prized for reliability in manual operation. With an accuracy of 0.02 mm/m, it meets the stringent demands of calibration technicians and industry professionals.

FAQs of 200 X 200MM MASTER LEVEL:

Q: How is the 200 x 200MM MASTER LEVEL used for precision leveling and calibration?

A: This master level is placed on the surface or machinery to be checked, aligning its beveled edges with the reference point. The bubble vials allow real-time monitoring of both horizontal and vertical leveling, providing precise adjustments for accurate calibration.Q: What are the primary benefits of using this master level over standard levels?

A: Unlike standard levels, the MASTER LEVEL offers ultra-high accuracy (0.02 mm/m) and dual-axis measurement. Its precision ground surfaces, hardened steel construction, and corrosion-resistant finish ensure superior performance and longevity even in demanding conditions.Q: When should I use the MASTER LEVEL in my workflow?

A: Use the MASTER LEVEL during installation, setup, maintenance, and recalibration of machinery, equipment, or precision platforms where strict leveling tolerances are required. Its high resolution is valuable for both initial alignment and routine quality checks.Q: Where is the MASTER LEVEL best suited for use?

A: This tool is ideal for environments requiring precise calibrationsuch as industrial manufacturing, machine shops, quality control laboratories, and research facilities. Its robust build and manual operation enable use in both indoor and outdoor settings.Q: What is the proper process for maintaining the MASTER LEVEL?

A: After each use, clean the surfaces gently to remove any debris or residue. Store the tool in its protective case to prevent scratches or exposure to moisture, ensuring the precision ground surfaces and vials remain intact for accurate future use.Q: How does the beveled edge design benefit alignment tasks?

A: Beveled edges facilitate easy placement and alignment on narrow or irregular surfaces, improving contact reliability and enhancing measurement accuracy during both setup and verification processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Master Level Category

RSK 300 * 300

Price 21000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Powder Coated MS

Accuracy : 1% FSD

Block Level 0.02mm

Price 8500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Accuracy : 0.02 mm

Color : Black And Grey

Product Type : Block Level 0.02mm

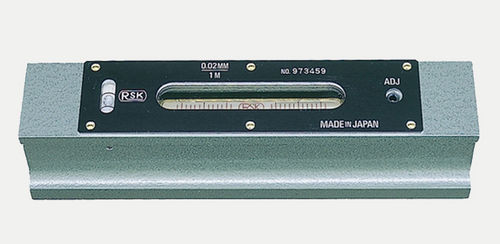

RSK Japan 200mm Block Level

Price 9500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Accuracy : 0.02 mm

Color : Grey

Product Type : RSK Japan 200mm Block Level

RSK 150*150MM FRAME LEVEL

Price 17000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Aluminium frame with polished surface

Accuracy : 0.5 mm/m

We mainly deal in Gujarat

Back to top

Send Inquiry

Send Inquiry