- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- PH Meter HANNA

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- DFT-222 Coating Thickness Gauge

- Hegman Gauge

- Digital Coating Thickness Gauge Accu-456B

- Digital Coating Thickness Gauge ACCU-356B

- Digital Coating Thickness Gauge DFT-111

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

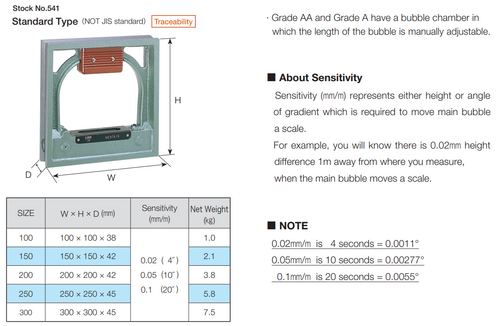

RSK 150*150MM FRAME LEVEL

Price 17000 INR/ Piece

MOQ : 1 Piece

RSK 150*150MM FRAME LEVEL Specification

- Measurement Range

- 0 - 150 mm horizontally and vertically

- Protection

- Shock-resistant body

- Sensor Type

- Bubble vial

- Application Media

- Frame alignment, machine setup

- Material

- Aluminium frame with polished surface

- Accuracy

- 0.5 mm/m

- Display Type

- Analog (Bubble vial)

- Range

- 150 x 150 mm

- Length

- 150 mm

- Equipment Type

- Frame Level

- Vials

- 2 bubble vials (horizontal and vertical)

- Weight

- Approx. 0.5 kg

- Finish

- Polished silver

- Edge Type

- Machined edges for precision

- Width

- 150 mm

- Mounting

- Flat base for stable placement

RSK 150*150MM FRAME LEVEL Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

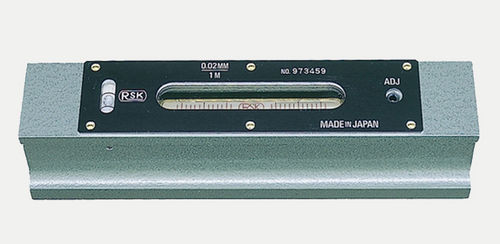

About RSK 150*150MM FRAME LEVEL

Grade AA A and B are manufactured and inspected

under the JIS B 7510 standard

See P5 for further information on each grade

Grade AA has 02 scale all range accuracy in the

main bubble

These three types have less than 3m accuracy in

flatness between base and side 002mmm type

Squareness between base and both side is 0015mmm

002mmm for Grade A

Grade AA and Grade A have a bubble chamber in

which the length of the bubble is manually adjustable

Precision and Durability Combined

Manufactured from high-quality aluminium, the RSK 150*150MM Frame Level offers resilience and consistent accuracy. The machined edges and polished finish contribute to both a refined appearance and reliable function, making this level suitable for demanding industrial settings.

Versatile Measurement Capabilities

Equipped with two bubble vials, this frame level allows for both horizontal and vertical measurement over a 150 x 150 mm range. The analog display ensures classic feel and swift readings, making alignment and machine setups straightforward for users in various environments.

FAQ's of RSK 150*150MM FRAME LEVEL:

Q: How do you use the RSK 150*150MM Frame Level for machine alignment?

A: To use, simply place the level's flat base on the surface you wish to align. Observe the position of the bubbles in the two vials to determine if the surface is horizontally and vertically level within the 0.5 mm/m accuracy.Q: What are the main benefits of this frame level's aluminium construction?

A: The polished aluminium frame ensures the level is lightweight for easy handling, resists corrosion, and offers excellent shock resistance for durability during frequent use.Q: Where is this frame level typically applied?

A: This frame level is commonly used in machine shops, manufacturing lines, and by maintenance teams for precise frame alignment and setup of various equipment.Q: When should I choose an analog (bubble vial) level over digital options?

A: Analog levels like this offer quick, direct readings without batteries, are less prone to electronic failure, and are generally more rugged for daily industrial use.Q: What is the process for verifying the accuracy of the level?

A: You can check its calibration by placing it on a level surface, noting the bubble position, rotating the level 180 degrees, and confirming the bubble remains centered. If not, recalibration may be required.Q: How does the shock-resistant body enhance usability?

A: The robust, shock-resistant design protects internal components and maintains calibration even after accidental drops, ensuring consistent measurement accuracy.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Master Level Category

RSK 300 * 300

Price 21000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Powder Coated MS

Accuracy : 1% FSD

200 X 200MM MASTER LEVEL

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Hardened Steel

Accuracy : 0.02 mm/m

Block Level 0.02mm

Price 8500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Accuracy : 0.02 mm

Product Type : Block Level 0.02mm

Usage : For Industrial And Laboratory Use

RSK Japan 200mm Block Level

Price 9500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Accuracy : 0.02 mm

Product Type : RSK Japan 200mm Block Level

Usage : For Industrial And Laboratory Use

We mainly deal in Gujarat

Back to top

Send Inquiry

Send Inquiry