- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- PH Meter HANNA

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

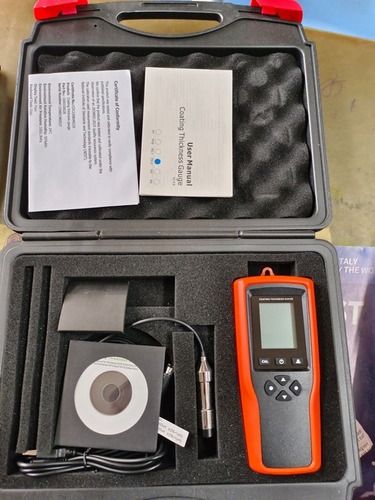

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge ACCU-356B

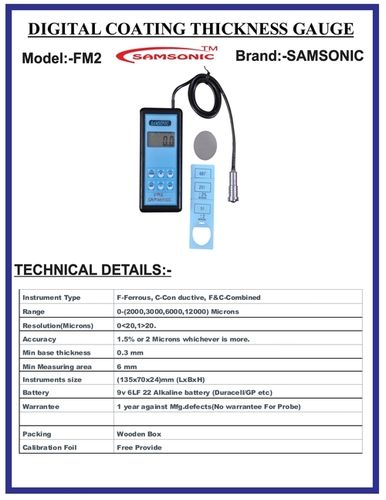

- Digital Coating Thickness Gauge FM2

- Digital Coating Thickness Gauge DFT-111

- DFT-222 Coating Thickness Gauge

- Hegman Gauge

- Digital Coating Thickness Gauge Accu-456B

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

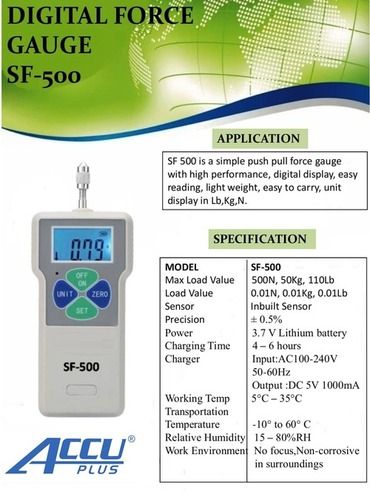

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore Hardness Tester

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

digital coating thickness Accu 3000fnf

Price 11000.00 INR/ Piece

MOQ : 1 Piece

digital coating thickness Accu 3000fnf Specification

- Display

- Large LCD Digital Display

- Sensor Type

- Integral probe (FNF dual) for both ferrous and non-ferrous substrates

- Case

- Hard Plastic Carry Case

- Outer Size

- 115 mm x 60 mm x 29 mm

- Measuring Range

- 0 1250 m (microns)

- Material

- ABS plastic housing

- Grade

- Industrial Grade

- Application

- Measures coating thickness of paint, lacquer, varnish, galvanizing films etc. on both ferrous and non-ferrous substrates

- Accuracy

- (1~3% + 1 m)

- Calibration

- Zero and foil calibration

- Resolution

- 1 m

- Power Supply

- 2 x 1.5V AAA batteries

- Minimum Curvature Radius

- Convex: 5 mm, Concave: 25 mm

- Standards Compliance

- Conforms to ISO, DIN, ASTM, BS standards

- Weight

- 90 g (including batteries)

- Data Hold

- Yes

- Storage Temperature

- -10C to 60C

- Minimum Substrate Thickness

- Ferrous: 0.5 mm, Non-Ferrous: 0.3 mm

- Backlight

- Yes

- Auto Power Off

- Yes

- Operating Temperature

- 0C to 40C

- Minimum Measuring Area

- 6 mm diameter

digital coating thickness Accu 3000fnf Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID)

About digital coating thickness Accu 3000fnf

Features and Functions 1m length separated probe Range 03000um, accuracy +/-21um 128*128dots LCD display Menu interface Red LED alarm indication LCD shows mean, maximum, minimum and standard deviation User can set alarm limit Readings can be stored, recalled and deleted Easy to do zero calibration and support multi-point calibration Connect with PC via USB and download readings Multi-language supported Up to 5 measurement groups supported Automatically detect the substrates type(F or N) Unit optional: um, mm and mils ApplicationsPrecise Dual-Mode Measurement

Equipped with an integral probe for both ferrous and non-ferrous materials, the Accu 3000fnf delivers reliable coating thickness readings with just 1 m resolution. The unit supports a wide measuring range (0-1250 m), making it versatile for different surface coatings, including paint, lacquer, or galvanized layers.

Robust Industrial Design

The compact ABS housing and lightweight build (90g including batteries) make this instrument highly portable. It operates effectively across a broad temperature spectrum and provides large, clear readings via its backlit LCD. The included hard plastic carry case ensures protection during transport and storage.

Ease of Use and Calibration

User-friendly features such as auto power-off, data hold, and quick zero and foil calibration streamline the measuring process. No special settings are required for substrate types, as the dual probe automatically distinguishes between ferrous and non-ferrous materials.

FAQ's of digital coating thickness Accu 3000fnf:

Q: How do I measure coating thickness with the Accu 3000fnf?

A: Simply place the probe on the coated surface. The device automatically detects the substrate type and displays the coating thickness instantly on the large backlit LCD. Ensure the surface area is at least 6 mm in diameter and meets the substrate thickness requirements.Q: What surfaces can the Accu 3000fnf measure?

A: This gauge can measure coatings on both ferrous (such as steel) and non-ferrous (such as aluminum) substrates. It is suitable for paint, lacquer, varnish, galvanizing, and similar coatings adhering to metal surfaces.Q: When should I calibrate the Accu 3000fnf device?

A: Calibration should be performed before initial use, after prolonged storage, or whenever measurement precision is critical. The gauge supports both zero and foil calibration methods for accuracy.Q: Where can I use the Accu 3000fnf coating thickness gauge?

A: The instrument is suitable for indoor and sheltered outdoor environments where the temperature is between 0C and 40C. It is ideal for automotive workshops, quality inspection areas, construction sites, and manufacturing lines.Q: What is the process for calibrating the device?

A: Calibration is straightforward: For zero calibration, place the probe on an uncoated substrate and follow the on-screen instructions. For foil calibration, use a calibration foil of known thickness, ensuring precise results in line with ISO, DIN, ASTM, and BS standards.Q: What are the main benefits of using this gauge?

A: Key advantages include non-destructive testing, quick and accurate measurements, automatic substrate recognition, portable design, and compliance with global standards-resulting in efficient quality assurance and reliable results.Q: Can I use the Accu 3000fnf on curved surfaces?

A: Yes, the device can measure on convex surfaces with a minimum radius of 5 mm and concave surfaces with at least a 25 mm radius, provided the minimum area and substrate thickness criteria are met.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Digital Coating Thickness Gauge Category

Video Borescope

Price 25000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : ABS Plastic, Stainless Steel Probe

Grade : Industrial

Display : 2.4 Color LCD Display

Application : Other, Pipe Inspection, HVAC, Automotive, Industrial Maintenance, Wall Cavity Inspection

digital coating thickness Accu CTG 2

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : ABS Body, Metal Sensor

Grade : Industrial

Display : Digital LCD Display

Application : Other, NonDestructive coating thickness measurement on metal substrates

DIGITAL FORCE GAUGE SF500

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : ABS and Metal

Grade : Industrial

Display : Large LCD Display

Application : Other, Tension and Compression Force Measurement

Digital Coating Thickness Gauge FM2

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Grade : Industrial Grade

Display : Digital

Application : Oil Refineries, Marine Engineering, Petro Chemical Plants, Mechanical Engineering, Nuclear Power Engineering

We mainly deal in Gujarat

Back to top

Send Inquiry

Send Inquiry