- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- Lux Meter (Light Meter) LX101A LUTRON

- INFRARED THERMOMETER MT10

- PH Meter HANNA

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- DFT-222 Coating Thickness Gauge

- Hegman Gauge

- Digital Coating Thickness Gauge Accu-456B

- Digital Coating Thickness Gauge ACCU-356B

- Digital Coating Thickness Gauge DFT-111

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Digital Shore Hardness Tester

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

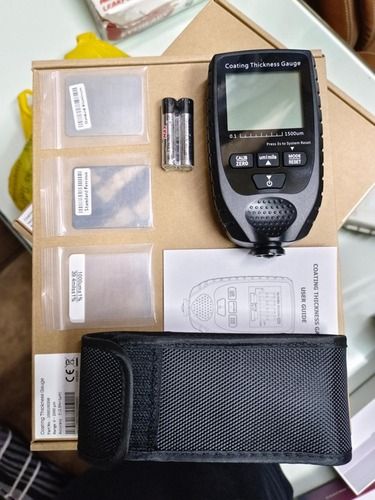

digital coating thickness Accu CTG 2

Price 4500 INR/ Piece

MOQ : 1 Piece

digital coating thickness Accu CTG 2 Specification

- Thread

- No Thread Required (Handheld Instrument)

- Case

- ABS Plastic Housing

- Sensor Type

- Integrated Ferrous/Non-Ferrous Probe

- Frequency

- Single Measurement Mode, Continuous Mode

- Display

- Digital LCD Display

- Measuring Range

- 01250 m

- Outer Size

- 155 x 75 x 35 mm

- Material

- ABS Body, Metal Sensor

- Working Presssure

- Atmospheric

- Grade

- Industrial

- Application

- Non-Destructive coating thickness measurement on metal substrates

- Accuracy

- (1% of reading + 1 m)

- Minimum Substrate Thickness

- Ferrous: 0.5 mm, Non-Ferrous: 0.3 mm

- Power Supply

- 2 x 1.5V AAA Batteries

- Resolution

- 1 m

- Minimum Curvature Radius

- Convex: 5 mm, Concave: 25 mm

- Data Output Interface

- USB / RS232 (optional)

- Standards Compliance

- ISO 2178, ISO 2360

- Weight

- Approx. 220 g (with batteries)

- Calibration

- 2-point calibration

- Operating Temperature

- 0C to 50C

- Storage Capacity

- Up to 400 readings

- Minimum Area Size

- Diameter 20 mm

digital coating thickness Accu CTG 2 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID)

About digital coating thickness Accu CTG 2

technical Specification

Principal magnetic Induction Probe N

range 0- 1300um 0-1300um

accuracy 3%+2um

Resolution 0.1um /0.01mil

0.01um/0.01mil

calibration points zero/50/100/250/500/1000um

units -um, mil

High Precision Measurement

Accu CTG 2 provides highly accurate readings with a resolution of 1 m and a measurement range of 0-1250 m. Its integrated ferro/non-ferro sensor ensures versatility when working with different metal substrates, complying with ISO 2178 and ISO 2360 standards. This ensures reliability in industrial quality checks and process validations.

Effortless Calibration and Usage

Featuring a simple 2-point calibration process, the Accu CTG 2 enables quick setup for immediate operation. The lightweight, handheld device does not require any threaded connection. With continuous and single measurement modes available, users can easily adapt the instrument for both rapid inspections and detailed analysis.

Data Management and Connectivity

The gauge is equipped with onboard storage for up to 400 readings and supports data export through USB or optional RS232 interfaces. Its digital LCD display ensures clear visibility, while battery operation (2 x 1.5V AAA) offers flexibility for field and on-site measurements without the need for constant recharging.

FAQ's of digital coating thickness Accu CTG 2:

Q: How does the Accu CTG 2 gauge measure coating thickness?

A: The Accu CTG 2 operates using an integrated Ferrous/Non-Ferrous probe, which utilizes electromagnetic principles to measure coating thickness on metal substrates without damaging the underlying material.Q: What calibration process is required before using this instrument?

A: The Accu CTG 2 utilizes a 2-point calibration method. Users simply follow the on-screen guided steps with reference standards to ensure measurement accuracy before beginning their tests.Q: When should I use the single or continuous measurement mode?

A: Single measurement mode is ideal for precise, isolated readings, while continuous mode helps when scanning large surfaces or performing multiple measurements rapidly during quality inspections.Q: Where can the data recorded on the Accu CTG 2 be transferred?

A: Data stored on the device can be exported via the built-in USB interface or through an optional RS232 interface for easy integration with PCs and data management systems.Q: What is the minimum area and curvature required for accurate measurements?

A: The minimum area size required is a diameter of 20 mm, with convex surfaces needing a radius of at least 5 mm and concave surfaces 25 mm for accurate results.Q: How is the Accu CTG 2 powered and what is its operating temperature range?

A: The device is powered by two 1.5V AAA batteries and is designed to operate within an ambient temperature range of 0C to 50C, making it suitable for a variety of working environments.Q: What are the primary benefits of using this coating thickness gauge?

A: This instrument offers non-destructive measurement, excellent accuracy ( 1% of reading + 1 m), portability, compliance with international standards, and user-friendly data management-making it ideal for industrial quality assurance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Digital Coating Thickness Gauge Category

Boroscope GL8898

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Measuring Range : Up to 1.5 m (Flexible Probe)

Accuracy : Highresolution Imaging

Material : Stainless Steel Probe, Plastic Handheld Unit

Grade : Industrial

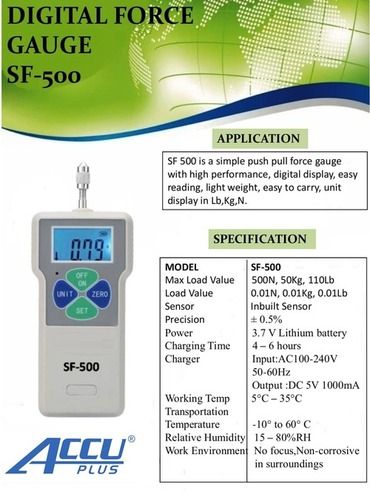

DIGITAL FORCE GAUGE SF500

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Measuring Range : 0500N (050kgf)

Accuracy : 0.5% F.S

Material : ABS and Metal

Grade : Industrial

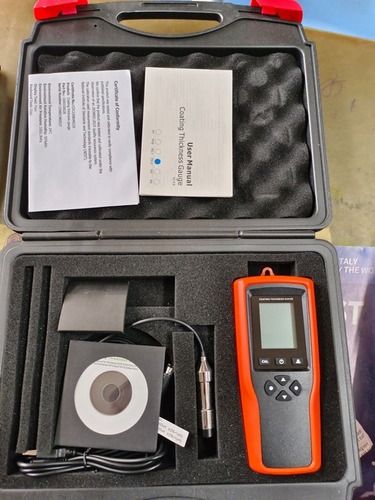

digital coating thickness Accu CTG-4

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Measuring Range : 0 1250 m

Accuracy : (2%+1m)

Material : ABS plastic housing, sensor tip material: stainless steel

Grade : Industrial

digital coating thickness Accu 3000fnf

Price 11000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Measuring Range : 0 1250 m (microns)

Accuracy : (1~3% + 1 m)

Material : ABS plastic housing

Grade : Industrial Grade

We mainly deal in Gujarat

Back to top

Send Inquiry

Send Inquiry