- Home Page

- Company Profile

-

Our Products

- Scientific Testing instruments

- Lux Meter (Light Meter) LX101A LUTRON

- PH Meter HANNA

- INFRARED THERMOMETER MT10

- Hygro Meter

- Laboratory Testing Equipment

- INSPECTION MIRROR

- O2 Meter

- PM-9102 Manometer

- PM-9100 Manometer

- PM-9107 Manometer

- PM-9100HA Manometer

- VB-8200 Vibration Meter

- VB-8202 Vibration Meter

- VT-8204 Vibration Meter

- EMF-822A

- Pull Off Adhesion Tester 1064

- SL-4010 Laboratory Testing Instruments

- SL-4011 Lab Testing Instrument

- SL-4030 Lab Testing Instrument

- LX-1102 Lab Testi152

- LX-1108 Lab Testing Instrument

- Sound Level Meter

- Hygrometer .

- Non Contact Tachometer

- Sound Level Meter

- Sound Level Meter Sl40001

- ANEMOMETER AM4201

- ANEMOMETER AM4200

- Infrared Thermometer

- INFRARED THERMOMETER MT22

- INFRARED THERMOMETER MT16

- HUMIDITY AND TEMPRATURE METER HT305

- Accu Plus Measuring Instruments (507024)

- Surface Roughness Gauge

- surface roughness tester accu 120

- Roughness Tester

- Surface Profile Gauge

- Shot And Grit-Blasting Comparators

- Digital Surface Profile Gauge

- Dust Contamination Tape

- Time 3100 Surface Roughness Tester

- Surface Roughness Tester Accuplus

- Surface Roughness Meter TIME 3220

- SJ210 Mitutoyo Surface Roughness Tester

- SA 2.5 Sand And Shot Blasting Chart

- 130 Roughness Comparison Specimens

- SURFACE ROUGHNESS CHART SA2.5

- SURFACE ROUGHNESS CHART SA3

- SURFACE ROUGHNESS CHART C9 GAR

- surface roughness tester accu 200

- surface roughness tester accu 210

- Magnaflux NDT Products

- Dye Penetrate Test Kit

- Dye Penetration Material Magnaflux

- 7C Black Wet Method Dry Powder

- WCP-2 Contrast Paint

- Spotcheck SKC-I Solvent Cleaner

- Water Washable Penetrant

- Spotcheck SKD-S2 Developer

- Spotcheck SKL-SP1 Penetrant

- Y7 Magnetic Particle Yoke M/C

- Magnaglo MG-2410 Wet Method Fluorescent Magnetic Powder

- 7HF Black Magnetic Particle Wet Method Prepared Bath

- Magnetic Flux Indicators

- Magnetic Particle Test Bar

- Magnavis Dry Method Non-Fluorescent Magnetic Powders

- Magnavis WCP-2 Contrast Paint

- Magnavis 9C Red Visible Wet Method Dry Powder Concentrate

- Magnavis 7HF Black Visible Wet Method Dry Powder Concentrate

- Magnavis 7C Black Visible Wet Method Dry Powder Concentrate

- Precision Measuring Instruments

- Portable Hardness Tester

- Digital Coating Thickness Gauge

- Digital Coating Thickness Gauge DFT-111

- Digital Coating Thickness Gauge Accu-456B

- Hegman Gauge

- DFT-222 Coating Thickness Gauge

- Digital Coating Thickness Gauge FM2

- Digital Coating Thickness Gauge ACCU-356B

- Wet Film Thickness Gauge

- Viscosity Cup

- Elektrophysik Coating Gauge

- DIGITAL COATING THIKNESS GAUGE ACCU 111A

- Video Borescope

- Boroscope GL8898

- video boroscope 9018

- digital coating thickness Accu 3000fnf

- Digital Coating Thickness Gauge F

- digital coating thickness Accu CTG 2

- digital coating thickness Accu CTG-4

- DIGITAL FORCE GAUGE SF500

- Welding Gauge

- Rubber Hardness Tester

- Hardness Tester

- Bluesteel Shore A Hardness Tester SHR - A - GOLD

- Digital Shore Hardness Tester

- Digital Shore A Hardness Tester

- Rubber Hardness Tester Shore A

- Bluesteel Rubber Hardness Tester Shore A And Shore

- Bluesteel Rubber Hardness Tester Shore A And Shore D

- SHORE A DIGITAL

- shore d digital

- Shore A Basic

- Shore D basic

- Shore A Export

- Shore d Export

- shore A Gold

- Shore d Gold

- NDT Instruments

- Digital Ultrasonic Thickness Gauge

- Pi Tape

- Laser Distance Meter

- Master Level

- Press-o-film

- Holiday Detector

- Paint Testing Instruments

- Scientific Testing instruments

- Know More

- Contact Us

Hegman Gauge

Product Details:

- Usage For Industrial And Laboratory Use

- Material Stainless Steel

- Grade Industrial Grade

- Application Oil Refineries, Marine Engineering, Textile Industry, Chemical Processing, Petro Chemical Plants, Pharmaceutical Manufacture, Mechanical Engineering, Nuclear Power Engineering

- Color Silver

- Width 10-50 Millimeter (mm)

- Click to View more

X

Hegman Gauge Price And Quantity

- 1 Piece

Hegman Gauge Product Specifications

- For Industrial And Laboratory Use

- 10-50 Millimeter (mm)

- Oil Refineries, Marine Engineering, Textile Industry, Chemical Processing, Petro Chemical Plants, Pharmaceutical Manufacture, Mechanical Engineering, Nuclear Power Engineering

- Industrial Grade

- Silver

- Stainless Steel

Hegman Gauge Trade Information

- 100 Piece Per Day

- 1 Days

- All India

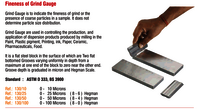

Product Description

AHegman gauge, sometimes referred to as agrind gauge,grind gage, or grindometer, is an instrument which indicates the fineness of grind or the presence of coarse particles and agglomeration in adispersion.[1]It is commonly used to determine how finely ground the particles ofpigment(or other solid) dispersed in a sample ofpaint(or other liquid) are. This is important because many types of solid materials must be ground into finer particles in order to be dispersed in liquids.[2]The resulting properties of the dispersion vary based on the size of individual particles and the degree which they are dispersed.

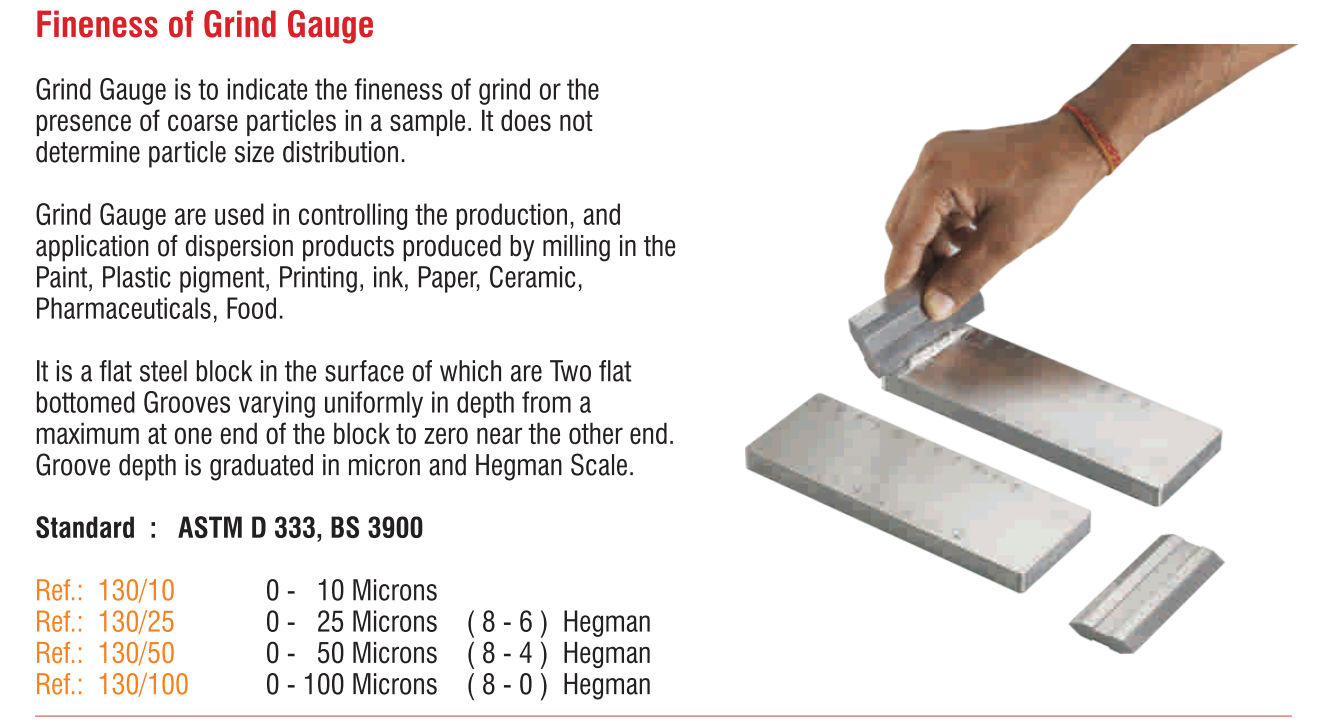

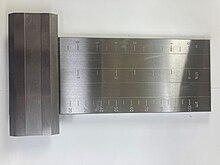

The Hegman gauge usually consists of a stainless steel block with a series of very small parallel grooves machined into it. The grooves decrease in depth from one end of the block to the other, according to a scale stamped next to them. A typical Hegman gauge is 170mm by 65mm by 15mm, with a channel of grooves running lengthwise, 12.5mm across and narrowing uniformly in depth from 100 m to zero and used to determine

[edit]

A Hegman gauge is used by placing a sample of paint at the deep end of the gauge and drawing the paint down with a flat edge along the grooves. Grind gages are sold with machined flat drawdown bars specifically for this purpose. The paint fills the grooves, and the location where a regular, significant "pepperyness" in the appearance of the coating appears, marks the coarsest-ground dispersed particles.[3]This is the point where oversized particles start to appear in high density and determines the rating for that material.[4]The reading is taken from the scale marked next to the grooves, in dimensionless "Hegman units" (orNational Standardunits; NS) and/ormilsormicrometres.[5]Hegman units are defined in terms of an inverted size scale as shown below:[6]

Hegman Grind Gage and doctor blade

Hegman Grind Gage and doctor blade Paint sample at top of Hegman

Paint sample at top of Hegman Hegman after paint drawdown

Hegman after paint drawdown| Hegman Units | Mils | Microns |

|---|---|---|

| 0 | 4.0 | 101.6 |

| 1 | 3.5 | 88.9 |

| 2 | 3.0 | 76.2 |

| 3 | 2.5 | 63.5 |

| 4 | 2 | 50.8 |

| 5 | 1.5 | 38.1 |

| 6 | 1 | 25.4 |

| 7 | 0.5 | 12.7 |

| 8 | 0 | 0 |

A lesser-used scale, North (or PCU), is also occasionally employed in the paint industry. Like the Hegman scale, this is also inverted compared to the value in microns:

| Microns | North units |

|---|---|

| 0 | 100 |

| 10 | 90 |

| 20 | 80 |

| 30 | 70 |

| 40 | 60 |

| 50 | 50 |

| 60 | 40 |

| 70 | 30 |

| 80 | 20 |

| 90 | 10 |

| 100 | 0 |

Determining the fineness of a paints grind is important, because too coarse a grind may reduce the paints color uniformity,gloss, and opacity.[7]The Hegman gauge is widely used for this purpose because it requires minimal skill and only a few seconds work.[3]

Versatile Applications Across Multiple Industries

The Hegman Gauge is ideal for measuring particle size and dispersion in a variety of sectors including oil refineries, marine engineering, textile industry, chemical processing, petrochemical plants, pharmaceutical manufacturing, mechanical engineering, and nuclear power engineering. Its adaptability ensures reliable performance and enhanced quality control in both industrial and laboratory settings.

Durable Construction and Precise Dimensions

Manufactured from premium stainless steel, the Hegman Gauge offers outstanding resistance to corrosion and wear. Its silver color and variable width (10-50 mm) accommodate diverse user requirements. With an industrial-grade guarantee, this gauge delivers long-lasting durability and unwavering measurement accuracy.

FAQs of Hegman Gauge:

Q: How is the Hegman Gauge used in oil refineries and chemical plants?

A: In oil refineries and chemical plants, the Hegman Gauge is used to determine the fineness of grind and particle dispersion within various slurries, pastes, and samples, ensuring process efficiency and product quality.Q: What benefit does the stainless steel material offer for industrial applications?

A: Stainless steel imparts high resistance to corrosion and mechanical wear, making the gauge suitable for demanding environments and offering a longer service life with reliable measurements.Q: When should the Hegman Gauge be calibrated and maintained?

A: Calibration and maintenance should be conducted regularly as per manufacturer recommendations or before critical measurement tasks, especially in laboratory and high-precision industrial processes.Q: Where is the Hegman Gauge most commonly used in India?

A: The gauge is widely used across Indian oil refineries, chemical processing facilities, textile factories, pharmaceutical plants, and research laboratories due to its accuracy and dependability.Q: What is the process for measuring particle size with the Hegman Gauge?

A: A sample paste or dispersion is applied along the gauge; as it is drawn down its graduated scale, the point where particles become visible indicates their maximum size, providing consistent and quantifiable results.Q: How does using a Hegman Gauge benefit laboratory quality control?

A: It allows lab technicians to quickly assess grind fineness, helping ensure raw materials and final products meet stringent industry standards for quality and consistency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Digital Coating Thickness Gauge' category

We mainly deal in Gujarat

Back to top